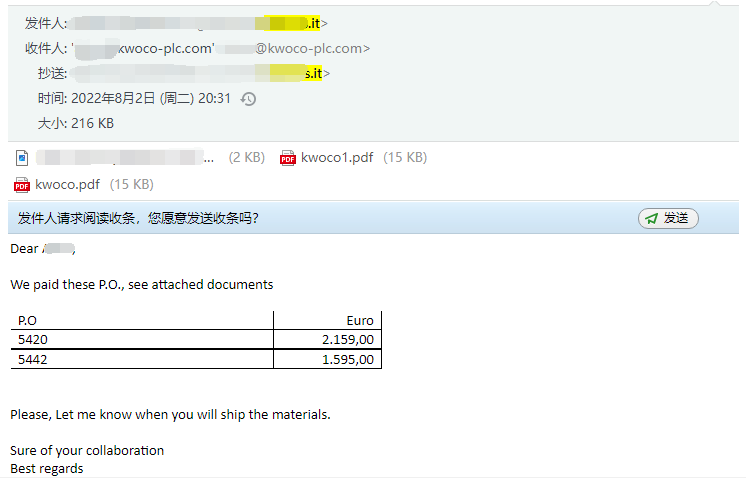

Collaboration Case with an Italian Packaging Machinery Manufacturer

Industry Challenges

Packaging machinery is a booming industry where automation parts from brands like Omron, Siemens, and Delta are widely used.

These crucial components ensure the efficiency and precision of production lines, but reliably sourcing them has been a persistent challenge.

Partnering for Success

Our client, a renowned Italian packaging machinery manufacturer, has been at the forefront of the industry for over 20 years.

They often faced issues like frequent stock shortages of essential parts or encountering counterfeit goods from unfamiliar suppliers, which jeopardized their operations, causing delays and increased costs.

Solution and Outcome

These issues were resolved when they partnered with KWOCO. We have ample stocks of brands like Omron, Siemens, and Delta, ensuring rapid order fulfillment.

Over years of cooperation, we have understood their production process’s critical needs and maintain safety stock for commonly used models, effectively solving the stock-out issues that troubled our client.

Our strict quality control measures ensure that all our products are sourced from verified regular channels, and we never allow counterfeit parts in our supply chain.

This has effectively prevented our clients from purchasing counterfeit products.

Relative to local European suppliers, we offer better price advantages with these brands.

Over the years, our relationship with this client has blossomed from mere transactions to a strategic partnership, continuously supporting their growth and innovation in the packaging machinery sector.

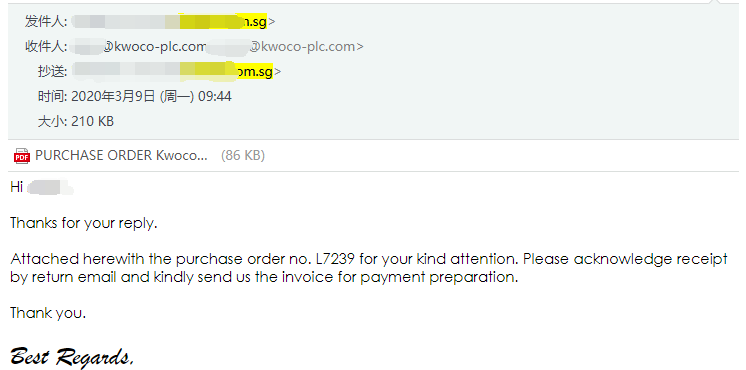

Collaboration Case with a Singapore Control Cabinet Manufacturer

Market Dynamics

Singapore boasts numerous distinguished equipment manufacturers with a strong demand for automation parts from renowned brands like Mitsubishi, Proface, and Omron.

Client Profile

Our client, a Singaporean control cabinet manufacturer, although small, has a great reputation in the industry.

They often encounter shortages of essential components. Although they have local suppliers, the diversity and variety of parts needed for control cabinets make one-stop shopping difficult, and local stock is often limited with long ordering periods.

How We Help

KWOCO offers them a one-stop purchasing service. We keep regular stock of commonly used models from brands like Omron, Mitsubishi, and Schneider, allowing for same-day shipping.

For example: Omron PLC, CJ1, CJ2, NX, CP… series; Omron HMI NB, NS… series; Mitsubishi MR-JE, MR-J3, MR-J4… series; Schneider Modicon M218, Modicon M238… and other series.

Our updated inventory system ensures we can promptly deliver these components to Singapore within 2-3 days after order confirmation, making procurement very convenient for our clients.

We also support our bulk purchasing clients with excellent price advantages, which local suppliers can’t match.

One-time deal is not what we are looking for, We are more willing to work hard for long-term cooperation between both parties.

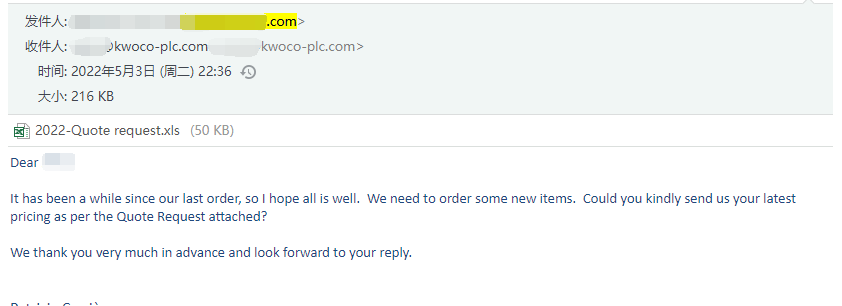

Collaboration Case with a Canadian CNC Equipment Manufacturer

Building Trust

We have good cooperation in Canada not only with some local traders, but also with some large equipment manufacturers in Canada. They have a great demand for Mitsubishi, Delta, Siemens and other products.

Client’s Needs

Our customer is a local manufacturer of CNC machine tools, although the purchase volume is not large, but the customer is very strict on the quality of the product.

Because machine tools have high requirements for precision and durability. Customers often use such as Mitsubishi, Siemens, panasonic and other brands of products.

Because of long-term cooperation, customers have a high degree of trust in us, often in the early stages of the project, will send some project requirements to us, hoping that we can help them to select the type.

Compared to them, we know more about these products, such as whether the products will be upgraded, discontinued or compatible.

Because the initial stage of each project, not only to consider the product performance, cost, but also need to consider the product later procurement is smooth.

For example, Mitsubishi from the HF series to the HG series, every year is constantly updating the product, many of the old models will face the risk of discontinuation, the new models need to consider compatibility.

We will report this information to the customer in advance, so that customers have a comprehensive consideration.

Overcoming Logistics Challenges

Our customers were very worried about the transportation and customs clearance of large goods in the early stages of cooperation.

With our professional knowledge and experience, we have given our customers confidence in cooperation again and again.

Because we have a freight forwarding company that we have cooperated with for more than ten years, they are very knowledgeable and professional about transportation, customs clearance and other related procedures in every country in the world.

Our products are shipped to most countries around the world, and the delivery time is only 3-4 days.

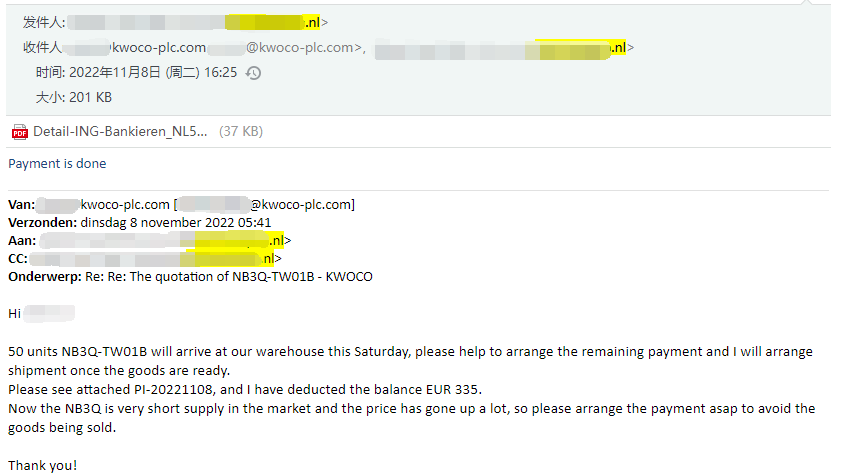

Collaboration Case with a Dutch Cutting Machine Equipment Manufacturer

Establishing Trust

Thanks to our good reputation, we have established a good relationship with many well-known factories in Europe.

Many factories in Europe rejected Chinese suppliers at the beginning of their cooperation, because many of them were attracted by cheap automation parts before, and after purchase, they realized that they had bought fake goods.

Because today’s market, there are too many fake goods disguised as new original goods for sale, many customers are attracted by their extremely cheap price and thus fell for it.

Meeting Client’s Demands

Our customer is a Dutch manufacturer of cutting machine equipment with several hundred employees. The customer has a high demand for Omron’s touch screen and Prof ace’s touch screen.

Because local purchasing of these parts in Europe often encounters out-of-stock or a long lead time, and we can fulfill the customer’s demand very well.

With the increase in the number of orders, customers often express their concerns about the after-sales of the products in the process of communication.

Because for these manufacturers, many of the products purchased back from the installation to the use of this cycle is very long, if there is a quality problem with the product is unlikely to be quickly found.

So we understand the customer’s concern. In the case of a product failure, our quick response left a deep impression on the customer.

We can assist with fast after-sales for brands like Omron, with all service provided by the original manufacturers, and each service action accompanied by an official inspection report.

This reassurance allows our clients to purchase confidently, knowing any quality issues can be swiftly resolved.

Strengthening Relationships

After repeated successful collaborations, we have become a primary supplier for our clients, who have recommended us to other companies.

We deeply appreciate our clients’ trust and are even more committed to maintaining high standards in quality and service.

Conclusion

If you’re still struggling to find the right automation parts supplier, don’t hesitate to contact us. Let KWOCO help simplify your operations, reduce costs, and enhance productivity. Don’t let supply chain uncertainties affect your business.